Technical background reading

An excellent paper on MSR reactor safety, written by the Egyptian Nobel Peace Prize winner, Mohammed Elsheikh Badawy is available online at http://www.sciencedirect.com/science/article/pii/S1687850713000101

Background for the general reader

Molten salt nuclear reactors (MSRs) were invented in the 1950’s. They operate at high temperatures (650 – 700oC) as for other reactors but have two key safety advantages:

(i) They run at low vapour pressure, so there is no great buildup of pressure inside the reactor vessel.

(ii)A solid salt freeze plug is built into the base of the reactor vessel. This only remains solid because it is cooled by a fan linked to the reactor power output. In the event of a power failure, the plug melts and the radioactive salt runs out of the reactor, into an emergency dump tank, causing the reactor to automatically shut down.

MSRs fell out of favour for political reasons but in recent years there has been a resurgence of interest in them.

The modern day attraction of MSRs is that they can operate using high grade radioactive waste material from water cooled reactors as fuel.

This solves two water cooled reactor problems relating to fuel costs and safety:

The cost problem: After four years inside a water cooled reactor, the tubes that retain the fuel pellets suffer radiation damage and have to be removed with the residual nuclear fuel abandoned as waste. This makes poor use of the fuel because only 3% has been consumed, with 97% remaining. However, the cladding can be removed and the “waste” material dissolved in molten salt, so that it becomes the fuel for MSRs. This means that the high level nuclear waste that has accumulated since the start of the nuclear age can be used as “free” MSR fuel.

The amount of waste available for recycling is estimated to be sufficient to run MSRs delivering the bulk of the world’s electricity for at least fifty years.

The safety problem: Our existing high level waste will remain dangerously radioactive for thousands of years. The waste material from MSRs only remains dangerously radioactive for a far shorter period of several hundred years.

1 The LP Turbine innovation

Latent Power Turbines can be used to simplify MSR reactor design, further improve their safety and improve their power generating efficiency.

Here are their key advantages.

(i) Existing MS reactors are run at their highest possible temperature to maximise their thermal efficiency. But this accelerates the rate of corrosion of the Hastelloy-N reactor core linings. In contrast, our proposed design runs ‘cool’, at the lowest possible temperature that the salt remains molten.

(ii) Improved safety.

The core can be cooled by natural air convection currents allowing the core to safely generate heat at full power, even if all of the electrical systems fail.

(iii) Improved power generating efficiency.

Existing designs of MSRs are intended to generate power using steam turbines that have a maximum thermal efficiency of about 50%. As we explain on our technical page, LP Turbines are inherently 100% thermally efficient, even though the Carnot efficiency of their internal heat engines is low.

2 A molten salt reactor modified for use with LP Turbines

2.1 The basic concept.

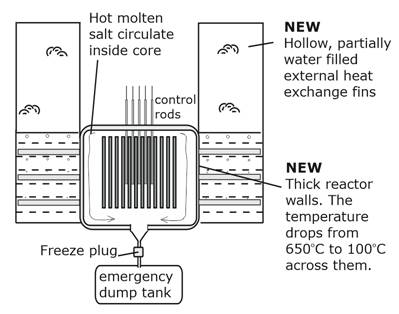

The following diagram illustrates new features we have added to the existing design.

Figure1. The existing MSR reactor design requires two new features in order to benefit from the incorporation of LP Turbines.

(i) The heat exchange fins warm a large volume of air around the reactor to just below 100oC.

(ii) The reactor walls are very thick, with the temperature dropping from 650oC inside the core to 100oC inside the fins. Thanks to the unusual nature of LP Turbines, there are no benefits in running the core at a higher temperature than 650o.

Hoop stresses due to the large temperature drop across the walls are reduced to an acceptable level by using a nested box construction, with the inner box being constructed from Hastelloy-N, the next box from lead (molten), then steel, then lead and so on.

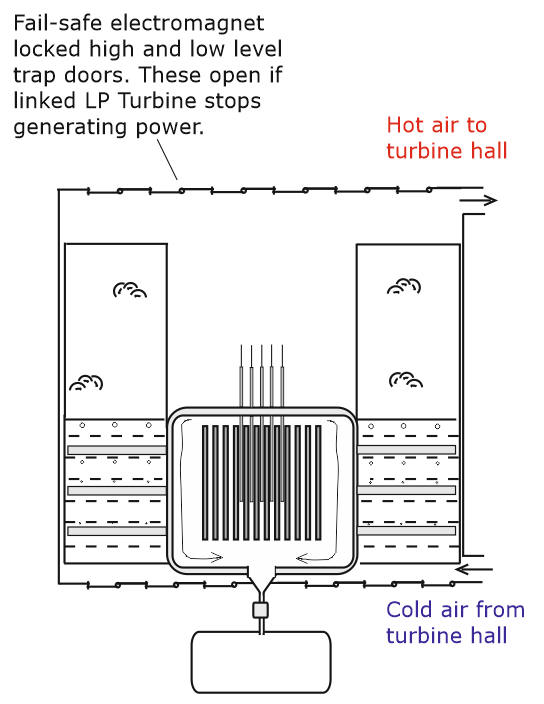

2.2 Collecting hot air for transfer to the LP Turbine hall under full power conditions

Figure 2. The reactor is housed inside a large containment building with trap door valves added to its roof and floor. Hot air enters the turbine hall from the top of the building and returns close to the building floor.

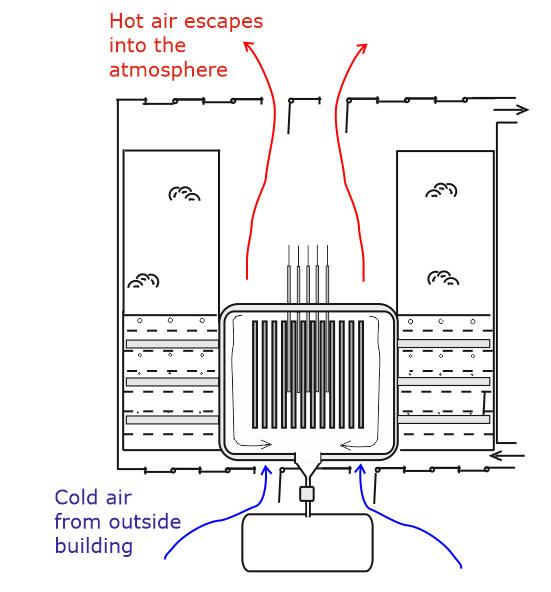

2.3 Response to a sudden failure of one of the loops of LP Turbines.

Each LP Turbine will be linked to a dozen or more others to form a closed loop. A large power station may require a hundred or more of these loops.

If any one of the loops fails to generate sufficient power, the corresponding trap doors will open, allowing external air to enter the building, to keep the reactor fins cool by natural convection. In the case of a major incident, where all of the LP Turbine loops fail to generate electricity, all of the trap doors open.

Figure 3. One pair of trap doors opens for each LP Turbine loop that fails.

3 Applications

Latent Power Turbines will make the existing national power grid with its nuclear power stations redundant. Instead, we can use the 'nuclear' electricity for applications that have previously been technically possible, but commercially unattractive because of the large amounts of energy required.

These new opportunities include.

- The large scale desalination of water by reverse osmosis.

- The extraction of valuable minerals and metals from sea water. For example, phosphorous, lithium and magnesium.

- Nitrogen fertiliser production using the Birkeland–Eyde process.

- The manufacturing of hydrogen on site, for use as space rocket fuel.

- The electricity could also be used for converting the rounded grains of desert sands into the much scarcer angular grains of sharp sand required by the civil engineering industries. [There is a looming world shortage of sharp builders sand; https://www.newscientist.com/article/mg23731650-300-world-without-sand-the-race-to-save-a-precious-resource/ .] The desert sand would be melted, and then cooled, to form glass. This would then be ground down to produce sharp edged sand grains.