A SUMMARY OF OUR PROPOSALS

- Latent Power (LP) Turbines

These extract heat from the environment and convert it into electricity.

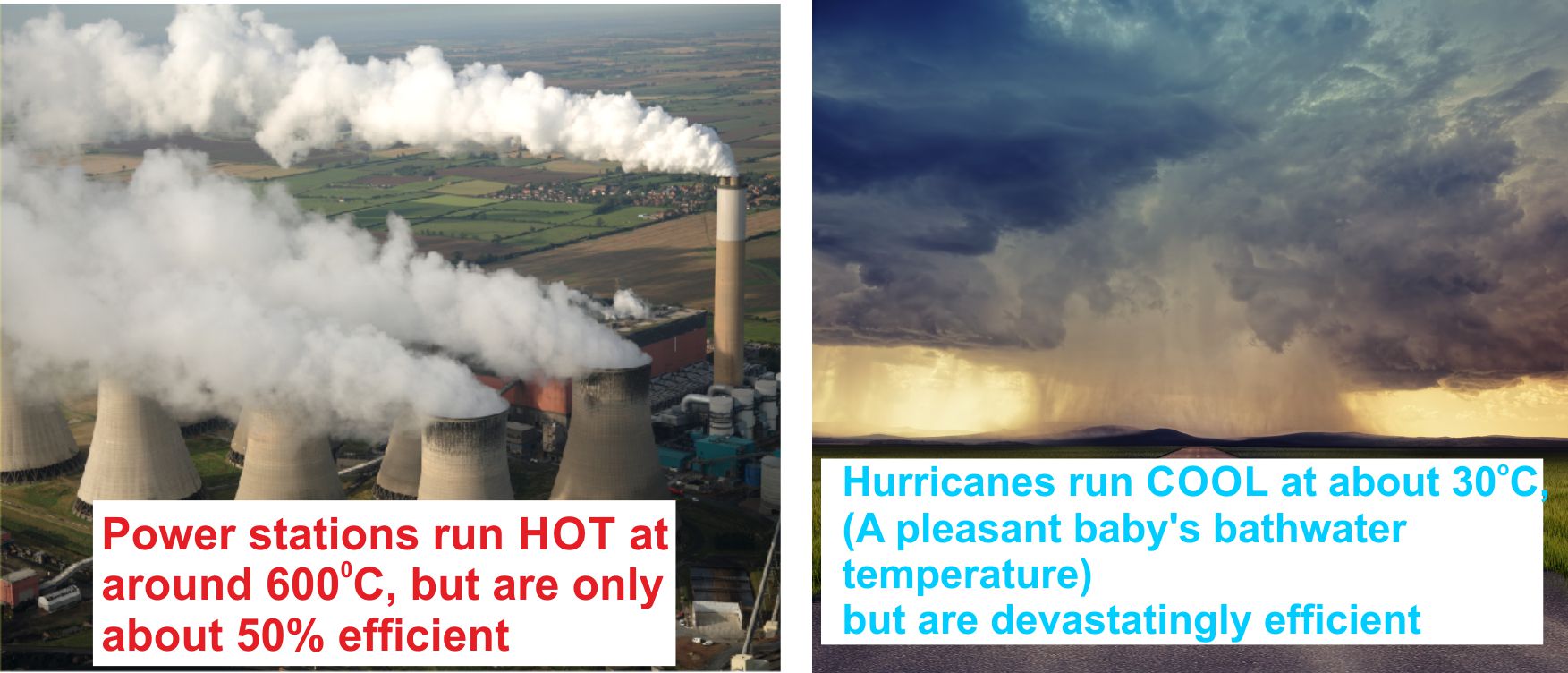

According to standard engineering textbook thinking this is impossible because the power station turbines and other heat engines that we use to generate electricity must run hot at about 600oC to maximise their efficiency. But nature knows different and has been running cool, efficient heat engines for millions of years. These are the heat engines that drive our weather systems. For example, tropical hurricanes are born at a temperature of around 30oC.

We have imitated nature by designing a heat engine that runs cooler than a baby’s bath water. As with nature, the trick to achieving high efficiency while running cool is that our power generator recycles its waste heat instead of dumping it into the environment.LP Turbines eliminate the need to build new nuclear power stations because they can deliver renewable energy 24/7, whatever the weather conditions.

- Wind down the use of natural gas

Clean electricity generated using LP Turbines will be a cheaper way of heating our homes compared with burning natural gas. - Using compressed hydrogen instead of petrol and diesel as vehicle fuel

Hydrogen would be an excellent alternative to batteries for powering vehicles. Hydrogen powered vehicles have greater range and they are quicker to fill up. But they are currently commercially uncompetitive.

Cheap, clean electricity in an LP Turbine era will solve the cost problem. - Capturing CO2 and recycling it

The cleanest way of manufacturing hydrogen is to pass an electric current through sea water, splitting it into oxygen and hydrogen. This produces oxygen as a by-product. We explain how this oxygen could be used to simplify the task of capturing CO2 from waste incinerators. - Converting organic (green bin) refuse and waste paper into biochar

In an LP Turbine powered world, converting green bin waste and paper into biochar is a greener option than composting or recycling them. Biochar is the name given to a form of charcoal used for improving the soil. Manufacturing biochar traps atmospheric CO2 for up to a thousand years. - Solving the plastic packaging dilemma

Plastic packaging has a lower carbon footprint than paper, but is difficult to dispose of. We explain how LP Turbines will help us get round this problem. - Eco-friendly smaller field farming

The big idea here is to replant hedges and return to the more environmentally friendly farming methods of the Victorian era. But we add some modern twists.

In order to keep productivity high and minimise labour requirements, horse drawn farm machinery would be replaced by swarms of robo-tractors. As a bonus, we suggest how this change in land use and improvement to the landscape could create new jobs in the rural tourism industry. - Expanding wetlands and improving river life

Wetlands are an important mechanism for locking up atmospheric CO2.

One of the benefits of our innovations is that less water will need to be pumped out of UK rivers. This makes more river water available downstream for irrigating estuarial wetlands. - Integrated vertical farms and high rise flats

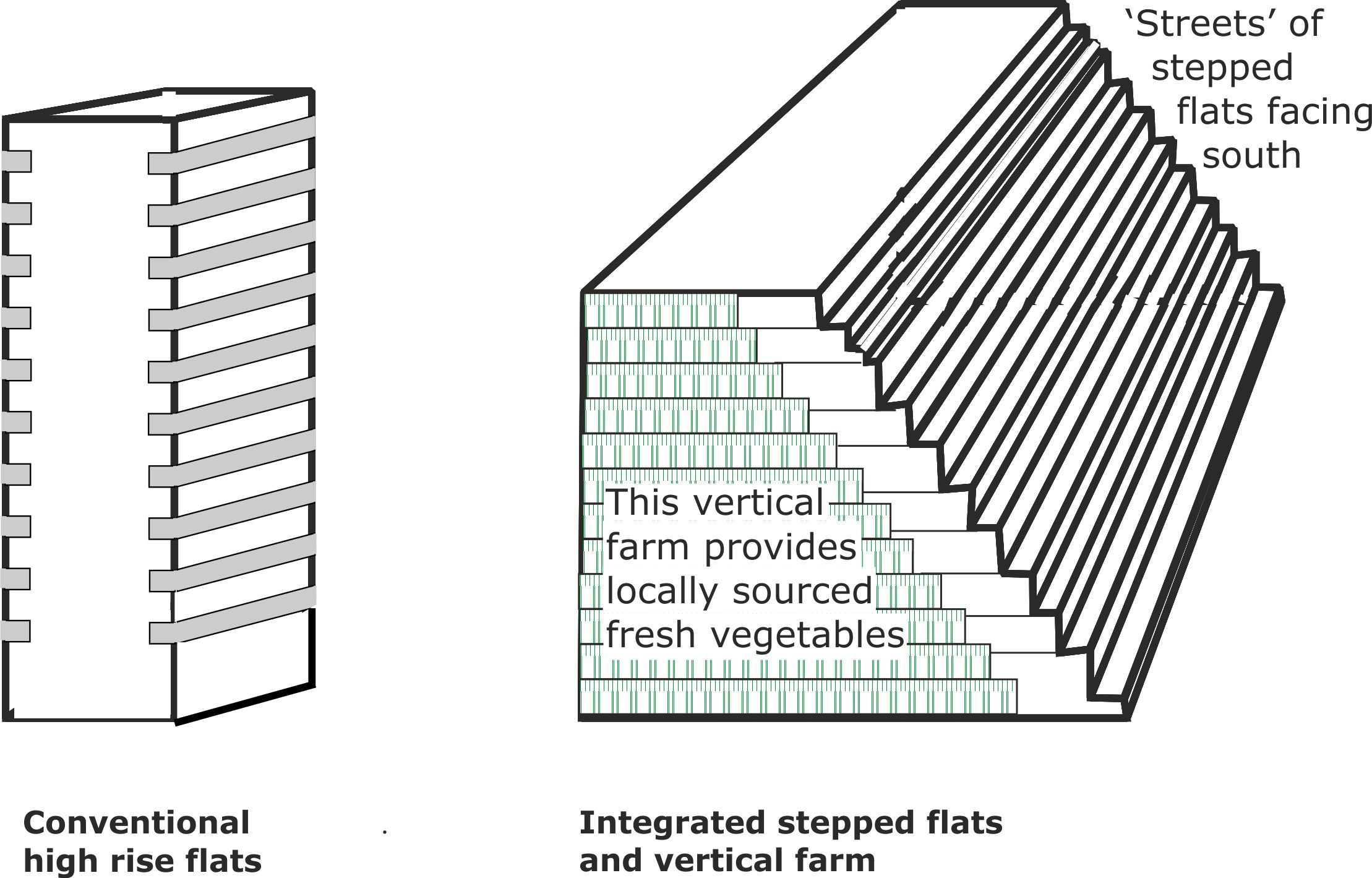

This is a ‘just in time’ solution to the problem of food wastage caused by consumers living at a distance from their food supplies.

It was inspired by the Grenfell Tower tragedy.

By building vertical farms inside high rise buildings we can improve their fire safety, eliminate food miles and provide residents with fresh food literally grown outside their front door.

Vertical farms also free up land for planting community forests to capture atmospheric CO2.

Intensive indoor farming requires lots of artificial light. LP Turbines can be used to generate the ‘green’ electricity required.

- Cancel HS2 and use the money to double the capacity of our existing rail network instead

According to conventional engineering thinking, there is a fundamental limit to the capacity of our existing rail network because metal wheels running on metal tracks have poor braking properties. We suggest a new contactless train braking technology that could double the passenger carrying capacity of our existing network. And, if we need to increase the capacity further, we also suggest a novel type of train propulsion system. By abandoning HS2 and ploughing the money into these innovations, Britain could develop a new manufacturing sector by 2025. - Building a new chemicals industry based on CO2

Switching from oil to CO2 as the basic feedstock for the chemicals industry is possible using existing technology but is commercially unattractive because of the high cost of the energy required. This disadvantage can be overcome in an LP Turbine era. - Incinerating our high level nuclear waste

The problem of nuclear waste has to be confronted, no matter what our views on nuclear power.

Radioactive materials can only be stabilised by altering the properties of their highly unstable nuclei. The only practical way of doing this is to incinerate the waste in molten salt nuclear reactors. We explain how Latent Power Turbines could significantly improve the safety of these reactors while still allowing them to produce large amounts of carbon free energy.

A climate bonus

About 99% of global warming is the result of atmospheric pollution causing a greenhouse effect. It will take a long time for these polluting gases to disappear, even if we stop polluting the atmosphere tomorrow. Meanwhile glacier melting will continue and sea levels will continue to rise.

But a tiny amount of heating is caused directly when we heat the air by burning wood or fossil fuels. So, each time we replace any form of fuel burning with an equivalent amount of energy produced using LP Turbines, we get a small, but instant reduction in global warming.

Do you want to help launch an LP Turbine based green revolution?

LP Turbine development is an open source project.

In order to help fight climate change, Latent Power Turbines Ltd has decided to abandon the profit motive and dedicate its invention to humanity.

With help, we will set up a charity that grants licences allowing any business or university worldwide to exploit our intellectual property for free. This means that there will be no licensing fees and businesses can keep all the profits they make without paying us a penny.

The only condition is that during the early years, when the basic design is still being refined, al licence holders agree to freely share any design improvements they make.

The principal shareholder and LP Turbine inventor, Bill Courtney has developed eyesight problems, so he will require assistance in setting up and running the charity.

The first step in the revolution is to create public awareness of LP Turbines and our free offer. In particular, we need open minded energy experts to become familiar with LP Turbine technology. With this in mind, Bill is keen to give seminars to academics and research groups, so they can debate his designs.

Please play your part in creating public awareness by spreading knowledge of LP Turbines and our offer using social media.

(Its' a lot less painful than alternative ways of playing your part in the fight against climate change, such as gluing yourself to the road.)

Thank you

A MORE DETAILED DISCUSSION

1 Latent Power Turbines

These are the key ingredient for several of the proposals, so they will be described in the greatest detail. I apologise for making this section so long and hope you will stick with me.

As a student in the 1960’s, I studied thermodynamics at university and as a hobby, developed an interest in meteorology. At university I learned that most of the world’s electricity and transport needs are met by a class of devices called heat engines.

Heat engines include petrol and diesel engines, old time steam engines, jet engines and the turbines in fossil fuel and nuclear power stations.

The efficiency myth

I was surprised to learn that manufactured heat engines are only about 50% efficient in spite of running very hot at around 600oC to maximise their efficiency. [Precise efficiency figures vary widely, depending on the type of heat engine and operating conditions.]

This means that approximately half of all the greenhouse gases we have pumped into the atmosphere by burning fossil fuels in these engines have served no useful purpose. Likewise with nuclear power; about half of the high level nuclear waste we have created has not delivered electricity.

Figure 1. Car radiators and power station cooling towers are only required because manufactured heat engines are so inefficient.

Since the industrial revolution, we humans have pumped about 375 billion tonnes of carbon into the atmosphere as carbon dioxide. The inefficiency of our heat engines means that at least half of this pollution has delivered no useful power for humanity.

Figure 2. Humanity has gained no tangible benefits for half of the carbon pollution of our atmosphere.

I have been raging about this waste since the 1960’s, long before I became aware of climate change.

This is the reason for my exasperation:

We humans are wasteful, but nature is not.

Meteorology had taught me that nature’s heat engines that drive our weather systems are very efficient, even though they run cool. The most impressive of these natural heat engines are tropical hurricanes. When they hit a city such as New Orleans they can do as much damage as an exploding nuclear warhead. But the highest temperature inside hurricanes is about 30oC. – The recommended temperature of a baby’s’ bathwater. Then I realised that nature had an even more impressive heat engine up its sleeve.

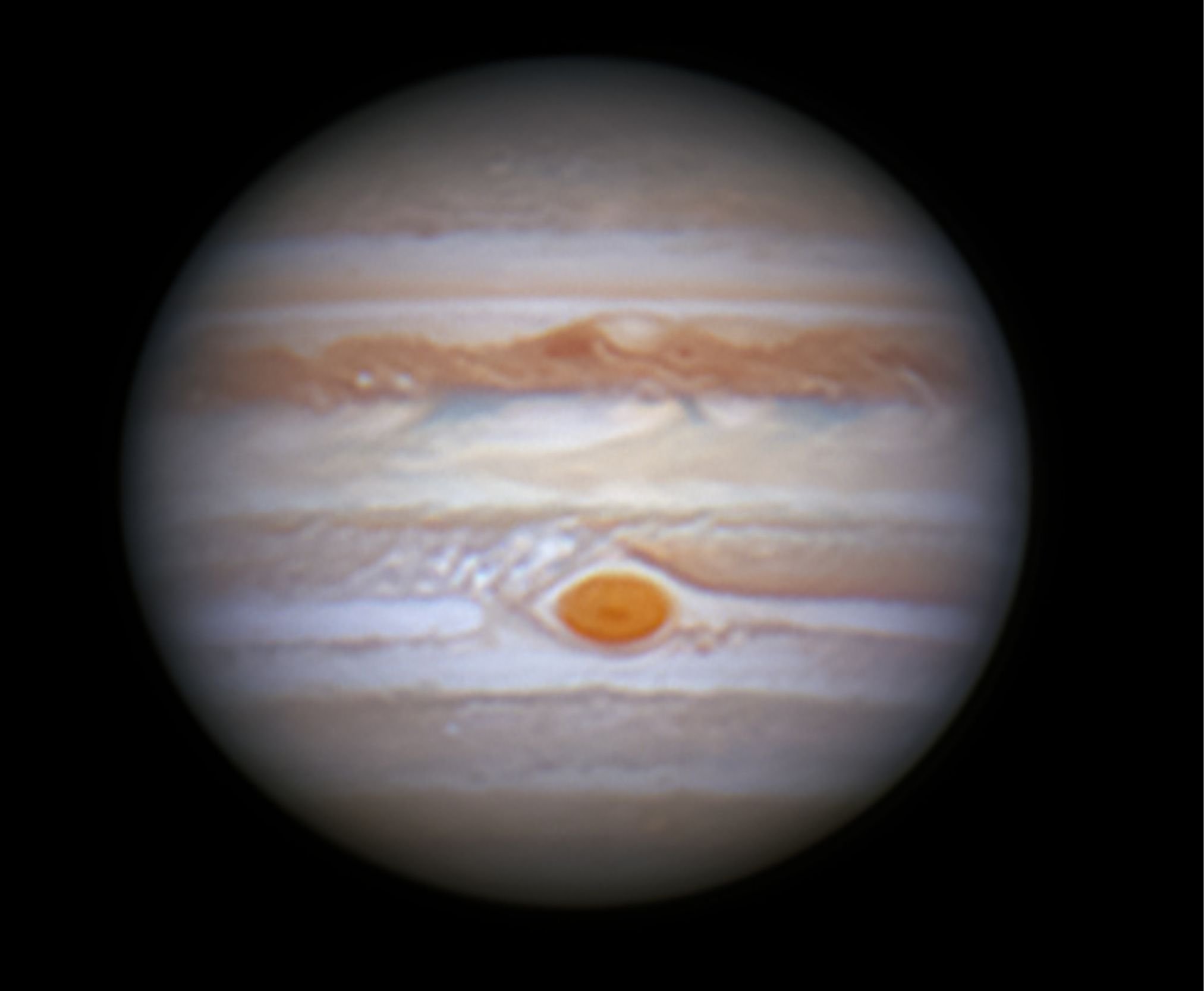

As a 14 year old I had been a member of Manchester Astronomical Society and was aware that violent weather systems existed on Jupiter, where the average temperature is a bitterly cold -145oC. Six years and one thermodynamics course later, I began to speculate on the prospect of a new type of heat engine that ran at very cold temperatures. This would defy everything my tutors taught me, by acting as a power generator and refrigerator at the same time.

My argument was simple.

“Why can’t we learn from nature and design a new type of highly efficient heat engine that runs cool?”

What is most surprising is that almost every engineer and scientist that I have spoken to during the last 50 years refuses to learn from nature.

The pessimistic ‘50% efficiency limit’ has been taught in universities since before the First World War. Therefore the experts conclude it must be true. And there is nothing we can do about it.

Figure 3. Power generating heat engines cannot match the efficiency of the heat engines found in nature.

So what is nature’s trick?

It’s very simple. Hurricanes and other natural heat engines recycle their waste heat instead of dumping it.

In contrast, none of the heat engines we have developed during the last 300 years have been able to recycle their waste heat.

What I concluded from my meteorology studies was that running heat engines cool and recycling heat probably went hand in hand. But this goes against the engineering wisdom of running heat engines as hot as possible in order maximise their efficiency.

It took me many years before I found a chartered engineer, Dick West, who was open minded enough to work with me. (In 2006 I became partially sighted and from then on, needed a skilled, sighted partner. Dick West was the ideal person. So, if you are impressed by what you read about LP Turbines, it’s important to recognise that this was a team effort.)

The engine we devised is our Latent Power (LP) Turbine.

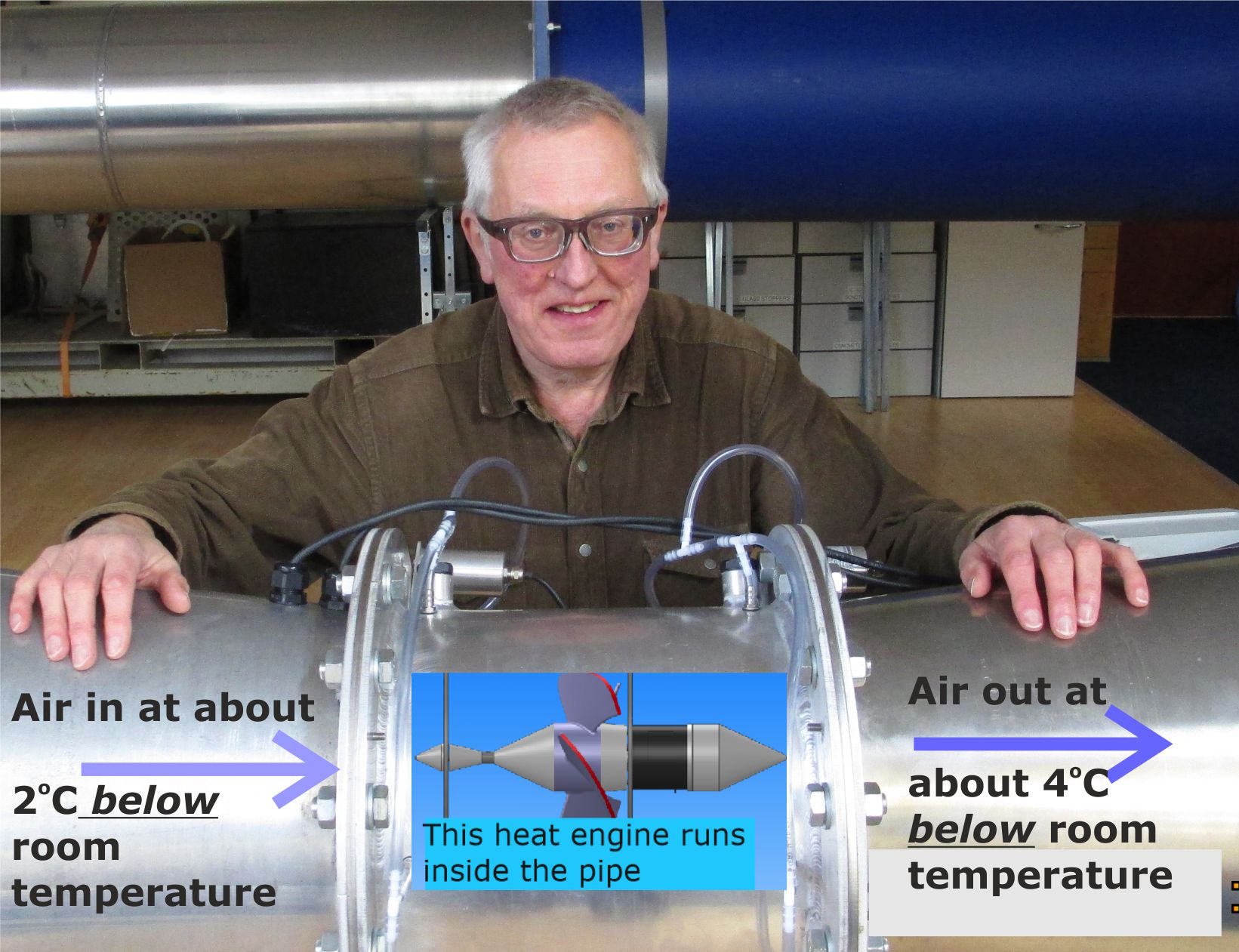

For our Mk 1 Turbine experiments at Lancaster University (2010) we started off by imitating tropical hurricanes, extracting heat from moist air at around 30oC. We then discovered that the experiments still worked well if we used dry air at a lower temperature.

Thanks to Innovate UK funding, we were then able to start work using a much larger Mk 2 Turbine.

A short description of the Mk 2 LP Turbine

Figure 4. The Mk 2 LP Turbine works by extracting heat from the air and converting it into electricity. This can only be done without violating the laws of thermodynamics because the heat engine runs cooler than the atmospheric air. We also copied nature’s recycling trick by using a closed loop system.

The ability of LP Turbines to generate electricity whatever the weather conditions will eliminate the need to build new nuclear power stations for power generation purposes.

Figure 5. When the Mk 2 LP Turbine was generating electricity my hands became cold because the heat engine was running at a temperature below that of the room. So, heat from the air and my body was being converted into electricity.

As we explain on this linked page, the laws of thermodynamics ensure that the LP Turbine always runs cold. This is true in the bitter depths of winter or the stifling heat of summer.

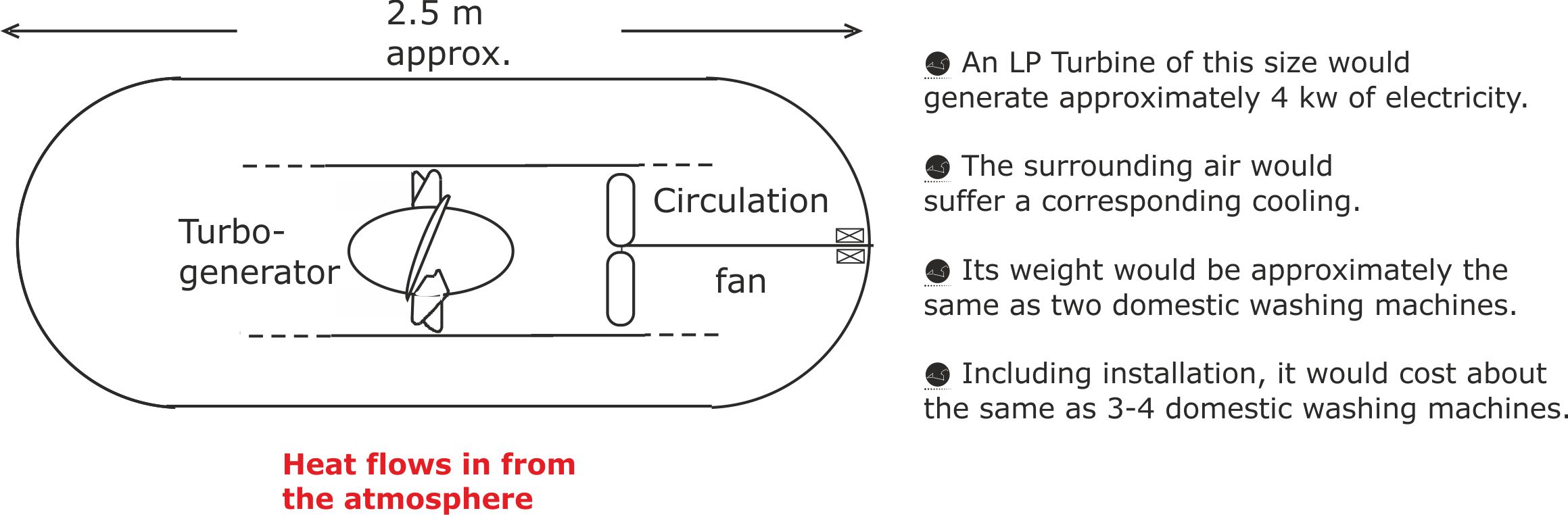

Our Mk 2 LP Turbine is very bulky, but this is deliberate because we wanted plenty of space inside the system to monitor the airflows. We have produced several more compact designs. This is one of them.

Figure 6. This is a cautious estimate of the size, weight and cost of a mass produced LP Turbine. If all the buildings in a city generated their own electricity using wall or roof mounted LP Turbines, the street air would cool slightly. But due to the heat island effect, street temperatures would still remain very slightly higher than in the surrounding countryside.

LP Turbines are destined to make profound changes to our society. You can get some idea of what these changes will be by reading the rest of this page. If you want even more information, then I suggest that you go to our Cheshire Innovation home page and click on the options under the Latent Power Turbines heading.

The SK6 bonus

According to the BBC, the electrical industry has a ‘Dirty little secret’, SK6 gas [https://www.bbc.co.uk/news/science-environment-49567197].

SK6 gas is widely used in large wind turbines and electrical switchgear as a means of suppressing electrical fires. Unfortunately SK6 is also a highly potent greenhouse gas. So if it leaks out, it reduces the benefits provided by clean wind turbine energy.

Fortunately ,locally installed LP Turbines eliminate this problem because they do not employSK6 gas.

Current state of development

Business uncertainty following the outcome of the 2016 Brexit referendum has caused the UK development of LP Turbines to stall.

The climate cannot wait until the post COVID-19 and Brexit problems are sorted out. So we have decided to make LP Turbine development into an Open Source Project.

We are willing to grants zero royalty development and exploitation rights to any number of companies and universities worldwide, on the condition that they share their designs as open source information, for the good of all. [Licenses granted subject to respecting UK laws on trade sanctions.]

In other words, any licence holder will be free to apply for research grants or make money out of manufacturing LP Turbines without having to worry about infringing LP Turbine intellectual property rights as described in patent applications WO 2012/007705 and GB 2531079.

Help needed

A charitable foundation will need to be set up to oversee the licensing and ensure that all license holders have access to the latest development work on LP Turbines. Please get in touch if you have the necessary skills or finance required.

(I have become partially sighted and need to step back from LP Turbine development.)

2 Wind down the use of natural gas

Clean electricity generated using LP Turbines will be a cheaper way of heating our homes compared with burning natural gas.

Early installers of LP Turbines will feel the financial benefits of eliminating their gas bills by 2025.

The spine of the existing network of natural gas pipes could find a new use, delivering hydrogen to vehicle fuelling stations and businesses.

3 Using compressed hydrogen instead of petrol and diesel as vehicle fuel

Figure 7. Vehicles designed to run on hydrogen are already on sale. They have a greater range than battery powered vehicles and are quicker to refill. But hydrogen fuel is expensive and, because of the way the fuel is made, may be less environmentally friendly than battery power.

The cost problem arises because considerable energy is required to make the hydrogen and then compress it for storage in fuel tanks.

The big environment issue is that currently the cheapest way of producing hydrogen is to make it out of natural gas.

Bringing down the hydrogen manufacturing cost

In an LP Turbine era, electricity will be generated locally, making the national grid and all the large fossil fuel and nuclear power stations that feed into it redundant.

Nuclear power stations could find a new role, generating electricity to make hydrogen. To make them more cost effective, they could be upgraded to double their efficiency. The upgrade would consist of using LP Turbines to harness the waste heat that nuclear power stations currently dump into the environment.

I am not a nuclear engineer, so I canno,t say for certain, but upgrading may safely prolong the working life of nuclear reactors by several years. During normal operations nuclear reactors raise high pressure steam at temperatures of 500oC to 600oC. But LP Turbines don’t need such high temperatures and pressures. They will work perfectly well if the reactors are run cool so that they generate steam at 100oC and atmospheric pressure.

Making the manufacturing of hydrogen greener

The greenest method of making hydrogen is by electrolysis of sea water. This involves passing an electric current through the water, splitting it into oxygen and hydrogen. Fortunately all UK nuclear power stations are situated on the coast. So they have ready access to all the sea water they need.

Alternatives to using nuclear power

(i) Heat could be extracted from coastal sea water to run a fleet of floating LP Turbines.

(ii) Hydrogen could be manufactured locally using shallow geothermal energy. See for example Figures 1 and 2 on this linked webpage.

An appealing feature of this option is that the geothermal heat could be extracted from abandoned deep coal mines. This would create new job in old mining communities.

Bringing down the hydrogen compression cost

The hydrogen needs to be compressed to about 600 atmospheres pressure in order to make it compact enough to store in vehicle fuel tanks. This requires a lot of energy and produces a lot of unwanted heat. In fact, about half of the energy used to compress the gas reappears as heat. Existing compression systems have little choice but to dump this heat in the environment.

LP Turbines slash the net amount of energy required for compression by half because they can recycle the heat of compression.

After being delivered by pipeline, compression could take place at the filling station or business premises.

Businesses and filling stations not connected to the pipeline could make their own hydrogen by electrolysis of water. The equipment for doing this is already for sale on the internet. The improvement that we are proposing is to drastically reduce running costs by using LP Turbines to make the required electricity.

Avoiding a recession in the car making industries

A switch to hydrogen powered vehicles could cause a temporary recession in the vehicle manufacturing industries while the range of hydrogen powered cars is being extended and a national hydrogen distribution network is setup.

This is the reverse of a problem that will be faced by a new LP Turbine manufacturing industry. Buying an LP Turbine will be cheaper than buying a new car and the purchase cost will be recovered in the form of lower energy bills in two or three years. Consequently, there is likely to be a rapid growth in LP Turbine sales, followed by a rapid fall as market demand is satisfied.

Both of these problems could be eased by temporarily switching production lines from motor vehicle to LP Turbine production.

Hydrogen and steel making

Coke is a fossil fuel that provides the intense heat for reducing iron ore to iron.

Burning hydrogen is just as effective and a lot cleaner. But hydrogen is more expensive.

This cost problem can be solved by using LP Turbines to manufacture hydrogen.

4 Capturing CO2 and recycling it

Municipal rubbish that cannot be economically recycled has to be buried or burned. In principle, the CO2 produced by existing incineration facilities could be captured and sequestrated (i.e., permanently disposed of by burial or other means.).

Using existing technology this is not a simple or cost effective proposition. The problem is that air consists of 78% nitrogen, 21% oxygen and 1% other gases. So when refuse is burned and the oxygen bonds with carbon to produce CO2, the flue gases are still predominantly nitrogen. Disposing of all this nitrogen along with the CO2 would be a costly and pointless exercise. So, according to conventional thinking, the CO2 has to be separated from the other flue gases before sequestration. But separating out the CO2 is expensive.

In an LP Turbine era, two new low cost methods become available.

First method

The nitrogen separation process is eliminated by burning the rubbish in pure oxygen, so the flue gases are almost pure CO2. This becomes cost effective in an LP Turbine era because oxygen is produced as a by-product when water is split by electrolysis, to make hydrogen for the transport market. [See Proposal 3 above.]

This method is particularly suited to authorities who use the heat of incineration to manufacture their own hydrogen by splitting water.

Second method

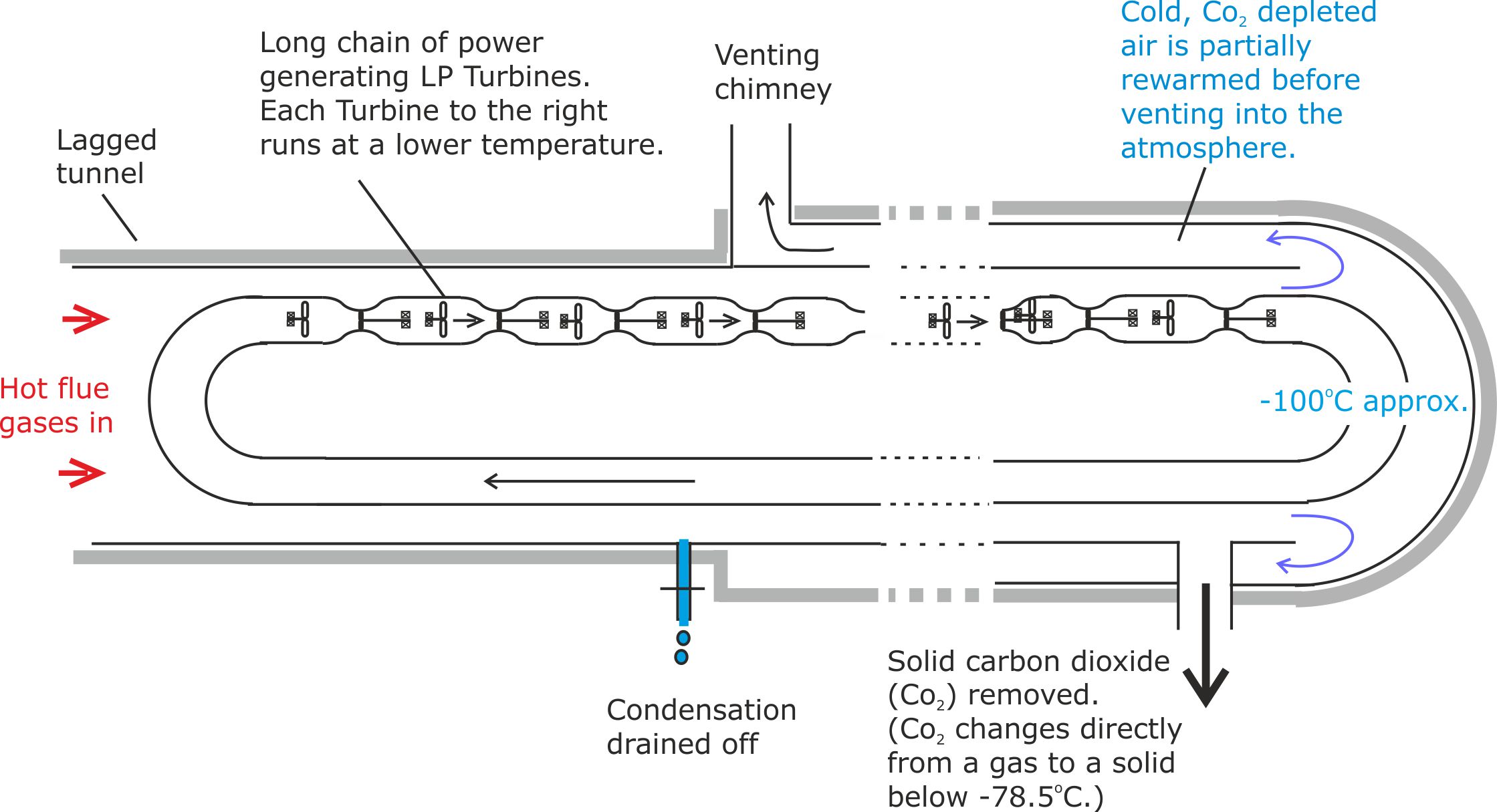

If the flue gases are cooled below −78.5oC, the CO2 will condense out as a solid (known as dry ice).

Our cooling method relies on the fact that LP Turbines cool their surrounding medium as they generate electricity. In this case, we use flue gases as the medium.

The diagram below illustrates the principles of the process.

Figure 8.

LP Turbines can operate at low temperatures.

The physical limitations on the lowest temperatures that can be reached are:

(i) The moving parts must not fail in the cold, due to brittle fracture.

(ii) The air circulating inside the LP Turbine must not turn to liquid. [Air turns to liquid at -194oC, well below the temperature we require.]

The manufacturing of iron, steel and cement all involve chemical reactions that result in the release of CO2. These greenhouse gases could also be captured in a similar manner to decarbonising flue gases.

This cool heat engine method of CO2 capture is counter intuitive because traditional heat engine run hot. However astronomy provides the evidence that very cold running heat engines are possible.

For example, the planet Jupiter has been running atmospheric heat engines cold (at temperatures below -145oC) since before the Earth was born.

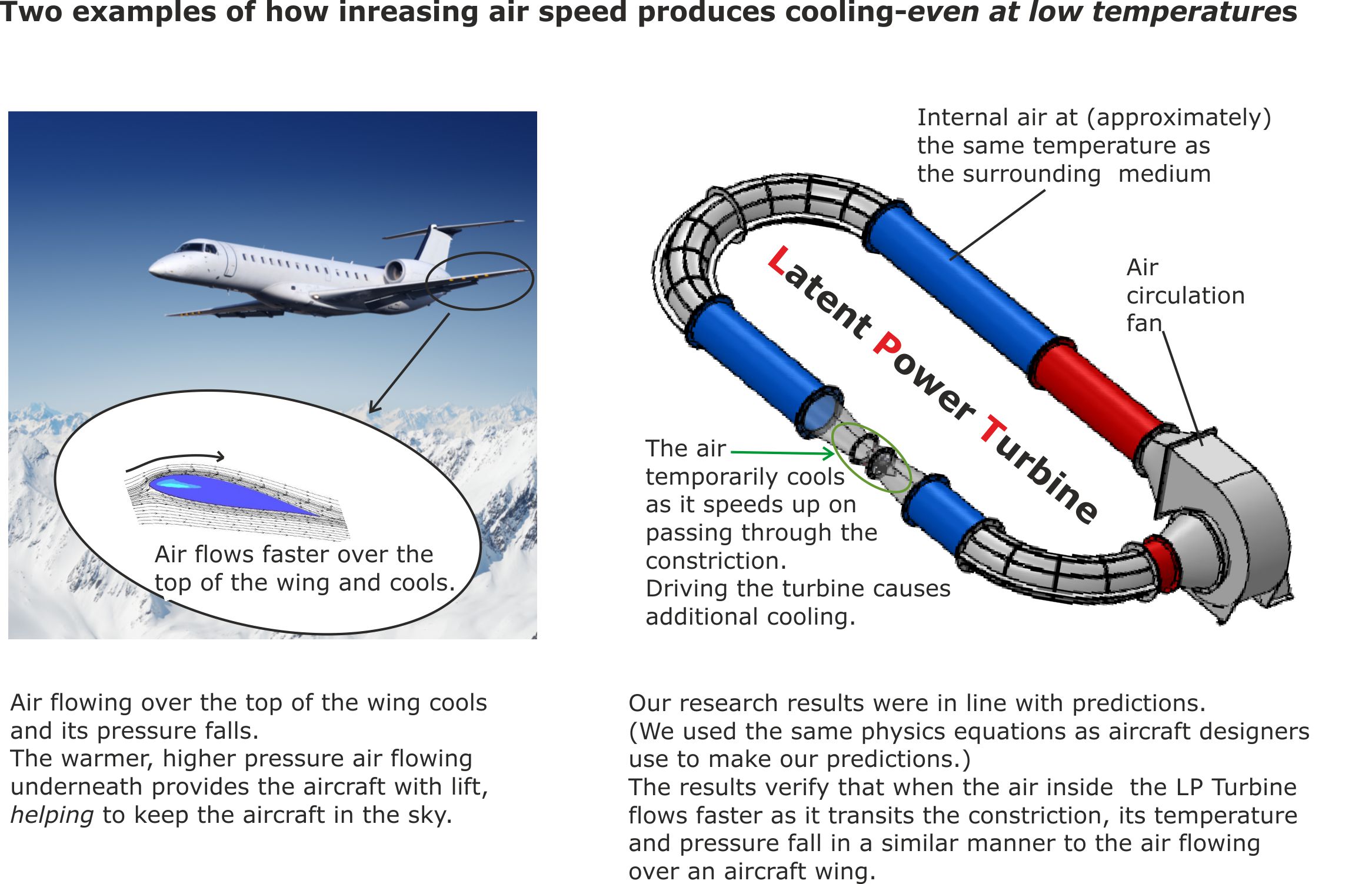

A more down to earth argument to convince sceptics is to point out that out that the physics of LP Turbines is similar to the physics that helps to keep aircraft in the sky, even when the air temperature is well below 0oC.

Here is a comparison between the air flowing through an LP Turbine and air flowing over an aircraft wing.

Figure 9. When air is forced to flow faster, whether over an aircraft wing or inside the constriction zone of an LP Turbine, its kinetic energy increases. In order for the first law of thermodynamics (conservation of energy) to be obeyed, the air temperature must fall to compensate.

The link between aircraft flight and cold running LP Turbines provides an opportunity for lateral thinking; it suggests how LP Turbines could solve the carbon problem created by flying.

Carbon dioxide constitutes about 0.04% of atmospheric air. So cold running LP Turbines could be used to capture atmospheric CO2 to offset the CO2 produced by airline flights. Passengers would be required to pay a surcharge to pay for the construction and maintenance of carbon capture units specifically constructed for this purpose. Monitoring this method of carbon offsetting would be far easier than monitoring offsetting schemes based on tree planting.

Making a profit by 2025 - 30

This carbon capture process will generate electricity and also a lot of very cold nitrogen. The nitrogen can be re-warmed by using it to freeze foodstuffs on an industrial scale. And the electricity generated can be used to cook the food before freezing. Thus, the cost of frozen food will fall while cleaning up incineration processes.

Any other industry that will benefit from access to copious amounts of very cold nitrogen could be converted from a carbon polluter to a carbon capturer in a similar way.

Recycling the CO2

In order to meet a 2025 target, the early batches of captured CO2 may be disposed of by injecting it into disused oil wells. But in the long term it will probably be used as a chemical feedstock for manufacturing a range of products including aircraft fuel. This will be discussed as Proposal 11 below.

OTHER APPLICATIONS OF CARBON CAPTURE BY COOLING

(i) Cement manufacturing and similar CO2 generating industries

Figure 10. Cement manufacturing accounts for about 8% of the CO2 dumped into the atmosphere.

[https://www.bbc.co.uk/news/science-environment-46455844]

Physically capturing the CO2 by flue gas cooling using an array of LP Turbines would generate ‘free’ electricity. This would reduce manufacturing costs for the industry.

(ii) Protecting the Antarctic and Greenland glaciers

A new green role for the oil companies

A variation on the design shown in Figure 8 could also be used on a large scale to protect coastal glaciers in the polar regions. Instead of cooling flue gases, the arrays of LP Turbines could be used to cool the warm ocean currents melting the coastal shelves of the glaciers.

The LP Turbines would be mounted on pontoons floating at a safe distance from the glaciers. The electricity generated could be used onboard to split sea water to manufacture hydrogen. The new generation of tankers required to deliver the hydrogen to customers would run off hydrogen or heat extracted from the sea using LP Turbines. So, even in the worst case accident scenario, there would be no oil spills.

If sufficient glaciers are protected, sufficient hydrogen will be produced to meet all of the world’s hydrogen needs. The oil companies are the ideal people for the job because they have built up a lot of expertise during their years of extracting oil from the cold North Sea. See Section 1.18 on this linked webpage for further details.

5 Converting organic (green bin) refuse and waste paper into biochar

In an LP Turbine powered world, converting these types of waste into charcoal is a greener option than composting or recycling them.

What is biochar?

Charcoal is a low density form of carbon. When it is used to improve soil or store atmospheric carbon, it is referred to as biochar.

If organic materials including paper are heated to their combustion temperature in oxygen or air then they burn creating carbon dioxide. But if they are heated to a similar temperature while being starved of oxygen then they break down to form biochar. This biochar can then be worked into the soil to improve its fertility. Archaeological evidence from the Amazonian rain forests verifies that biochar can trap carbon and improve the soil for up to 1,000 years. Biochar enriched soil would be something positive to leave to our great grandchildren, instead of a wrecked climate.

As a bonus, the vapours given off during biochar production can be condensed out as wood vinegar. This can be used as an organic fertiliser and insecticide. [http://www.biogreen-energy.com/wood-vinegar/]

The limitations of composting – We can’t leave it to the grandchildren

In the ordinary cycle of life, plants absorb CO2 from the atmosphere while they are growing and then release it again when bacteria break them down after death. Composting allows us to use the dead plant material to enrich the soil, but it cannot eliminate the decay process. So whether we compost organic material or not, the ordinary cycle of life only captures atmospheric carbon for a few years at most. In contrast, biochar production traps atmospheric carbon for up to a millennium.

A paper gift for the grandchildren

Manufacturing paper from wood pulp consumes more energy than making fresh paper from recycled paper. So, currently, paper recycling makes sense. However, in an LP Turbine powered economy where cheap clean energy is available, the environmental benefits of recycling paper are questionable. A better option would be to use paper once only, then convert it into biochar. More trees would need to be planted annually to meet the same level of paper demand. This may not sound too smart to anyone conditioned by the rallying call, “Save the trees”. But in fact it’s a good option, because it means that more carbon is being captured each year by the growing trees.

Also, we can trap the carbon stored in the whole of the tree above ground. Paper would be converted into biochar by the refuse collection authorities and the scrap wood and sawdust that never becomes paper would be converted close to the original forest site..

Adding biochar to soil is known to improve tree growth [https://www.carbongold.com/biochars-impact-on-tree-growth/]. So, both forest farming profitability and rate of carbon capture are increased when the forest is replanted.

Encouraging a biochar production mindset

Paper and organic waste refuse bins could carry a message that their contents are destined for biochar production. This would help to create a biochar manufacturing mindset where gardeners, farmers, stable owners and others become biochar manufacturing enthusiasts. It would also create a new industry, mass producing small biochar production units.

In an era of clean LP Turbine electricity, these would be electrically heated.

Figure 11. We need to give people some good news about how they can improve life for future generations. Otherwise they will just feel overwhelmed by the constant bombardment of bad news and switch off to environmental issues.

6 Solving the plastic dilemma: Biodiversity vs. greenhouse gases

The environmental harm done by single use plastic packaging is well documented [https://en.wikipedia.org/wiki/Plastic_pollution].

The ‘obvious’ solution is to replace plastic with paper and cardboard for packaging.

Unfortunately this has the unwanted side effect of accelerating global warming because manufacturing paper packing requires more energy than plastic manufacturing.

In an LP Turbine based economy, this dilemma would be resolved because cheap clean energy would be available for paper making.

7 Eco-friendly smaller field farming

Throughout Europe, many thousands of miles of farmland hedges have been removed to make space for larger items of agricultural machinery to be used.

In the UK alone, at least 80,000 miles have been lost since 1986. [https://www.independent.co.uk/news/uk/home-news/the-hedgerow-8000-miles-vanish-each-year-1360413.html]

Britain could take the lead in Europe by replanting hedges, but with a modern twist to an old idea..

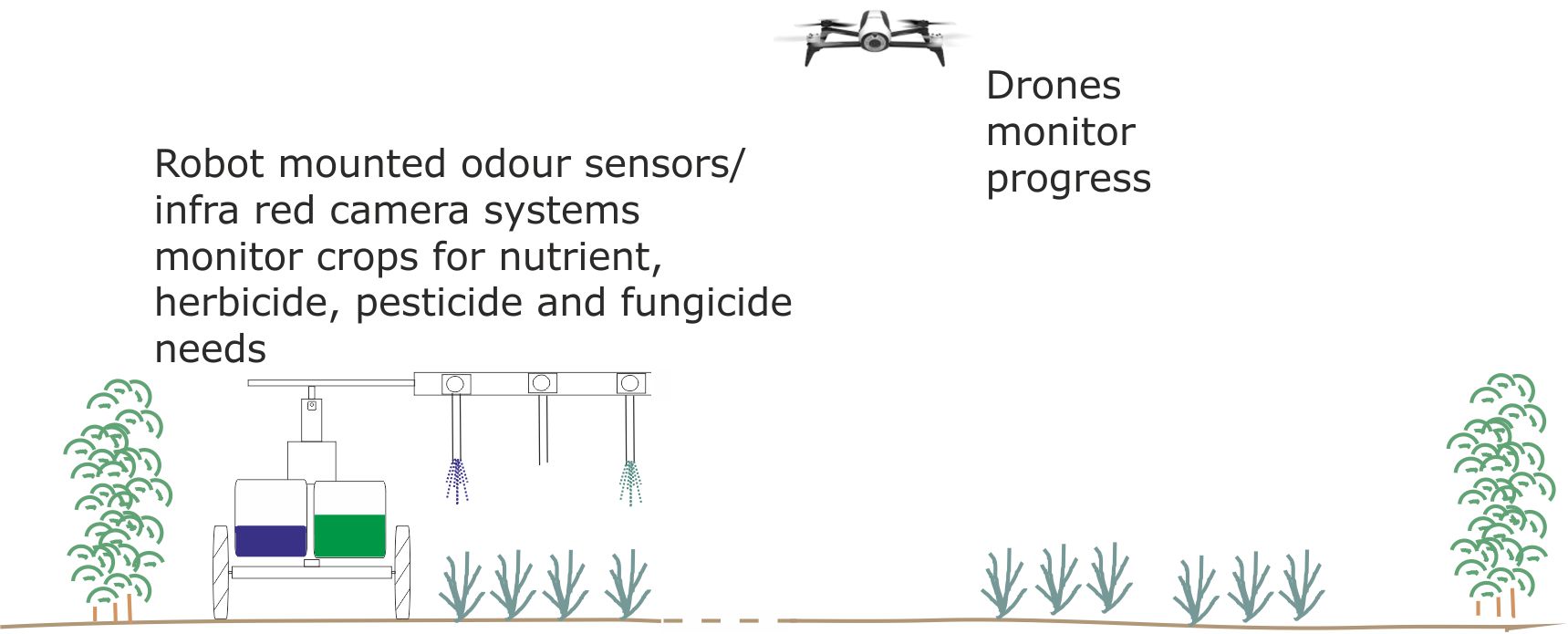

If swarms of small robo-tractors replaced the large items of agricultural machinery employed on British farms, we could return to a smaller field system. This would encourage bio-diversity and help the soil to recover, so that it retained more organic carbon.

To minimise their carbon footprint, the swarms would be fuelled by hydrogen.

Small robotic tractors are already being developed in several countries. But if Britain took the lead in developing hydrogen powered tractors, we could create a whole new manufacturing industry by 2025. British engineers with the required skills are already working hard in our armaments industries, but they may get more job satisfaction if their employers turned their hands to saving the planet. [In the long term, climate change is probably the biggest threat to world peace. So working towards a 2025 goal for net greenhouse emissions makes good military sense.]

Figure 12. The old way of doing things was romantic but grossly inefficient.

Remotely controlled robot tractors are a developing area of technology. By focusing development on small tractors that can manoeuvre in tight spaces, we could return to the smaller field systems of the Victorian era. A whole new range of miniaturised equivalents of the many big farm machines currently used by farmers will need to be developed. If British businesses supported by the British government move swiftly, we will be able to file patents to protect many of the designs.

Figure 13. Using swarms of small tractors instead of a large one allows greater precision in the application of chemicals to protect crops. This minimises the threat to biodiversity and pollution of watercourses.

Many weeds are becoming resistant to herbicides, making the physical removal of weeds a commerically viable alternative. Swarms of small robot tractors could be adapted for this role. [https://www.researchgate.net/publication/304916339_Technology_for_Automation_of_Weed_Control_in_Specialty_Crops]

Re-equipping farms with new types of machinery will cost money, but this investment for Britain will more than pay for itself over a few years. Here are some examples of the benefits.

¨ Smaller fields would protect river bio-systems by regulating rainwater flows and reduce silt flows into rivers. ¨ This would provide improved protection against the floods that are being aggravated by climate change. ¨ Rural communities could retain their young people by creating new jobs in the tourism industries.

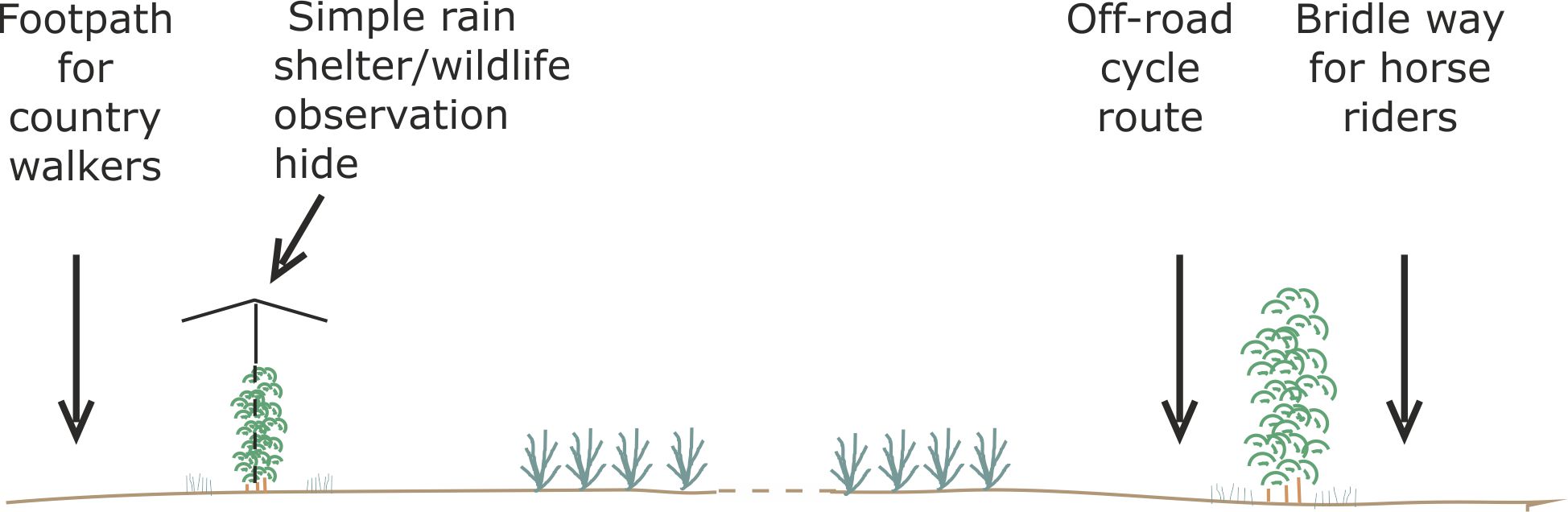

Tourism provides more jobs and wealth in rural communities than farming. The proposed small field system could include features to boost the tourist economy. Here are some examples.

Figure 14. Strips of land close to the hedges will be agriculturally unproductive. Some of them could provide routes for rural tourists. Many older and disabled bicycle riders are enjoying a new lease of off-road life thanks to the emergence of battery powered e-bikes. But their silent swiftness is causing problems for partially sighted walkers and horse riders. All the parties would be kept happy if we separated out their routes. And they would all work up a healthy appetite, creating business for country pubs and cafes.

These and other environmental benefits are discussed in detail on this linked webpage.

8 Expanding wetlands and improving river life

Our rivers and wetlands are a rich source of biodiversity. Wetlands also play a valuable role in storing carbon extracted from the atmosphere. Unfortunately, our modern lifestyle is draining away the water that rivers and wetlands need to thrive. We extract water to run our power station cooling towers, for manufacturing and domestic consumption and to irrigate farmland. In addition we interfere with the natural flow of rivers by building dams, for generating low carbon energy.

Here are some alternatives based on LP Turbines that are better for the environment and overall, will generate more income.

Water for power station cooling towers

If we replace conventional power stations with LP Turbines we will eliminate the need to extract power station cooling water from our rivers.

Figure 15. The clouds emerging from power station cooling towers are not harmful chemicals but tiny droplets of water formed by the condensation of steam. The water used to create the steam probably came from a local river or aquifer.

Manufacturing

Water is also evaporated to produce cooling in industries ranging from steel making to food processing. By switching to LP Turbines to produce cooling, businesses could save on their bills while protecting the environment.

Domestic consumption

In many cases, river water could be replaced by desalinated water. In an LP Turbine era this becomes economically viable using heat extracted from the sea to power the LP Turbines required. We discuss LP Turbine based desalination in detail on a linked web page.

In addition, when household LP Turbines are used for generating electricity in summer, moisture will condense on their external surfaces as dew. This could supply households with several litres of clean water per day, reducing the pressure on public water supplies.

Farmland irrigation

The addition of biochar to farm soils and their protection with replanted hedges would reduce the need for farmland irrigation. These measures will also reduce the rate at which water flows off the land after bursts of heavy rain. This will give the water more time to trickle down into the aquifers that keep the water levels under wetlands high.

Hydroelectric dams

These produce carbon free electricity but are an unreliable source of power because they depend on adequate rainfall. They may fall out of use as more reliable LP Turbines are introduced.

9 Integrated vertical farms and high rise flats

This is a ‘just in time’ solution to the problem of food wastage caused by consumers living at a distance from their food supplies.

According to The United Nations, roughly one third of the food produced in the world for human consumption every year — approximately 1.3,000,000,000 tonnes — gets lost or wasted. And of course, all of the chemicals used and energy expended in growing the wasted food has also been squandered. [http://www.fao.org/food-loss-and-food-waste/en/]

The problem is getting worse because the world population is rapidly growing and more people are moving into the cities, distancing themselves from their food supplies.

I propose that we Brits take the lead in solving this problem by completely rethinking how we house people in our cities.

[This proposal was inspired by the Grenfell Tower tragedy and is dedicated to the memory of those who died there.]

This proposal is not entirely new because farms inside skyscrapers have been producing local food for several years. [https://en.wikipedia.org/wiki/Vertical_farming] But, we have brought fresh thinking to the concept and reduced energy costs by incorporating LP Turbine technology.

Figure 16. A farm shop within the building sells direct to the residents. There are no food miles involved and the farmer will be in close contact with the customers, ensuring that the crops grown meet their needs. We discuss the many benefits of this type of dwelling on this linked page.

Indoor farming requires strong, good quality illumination. The jury is still out on whether vertical farms are truly green if we rely on existing power sources to generate the required electricity.

But these doubts will be eliminated if LP Turbines are used to generate the power. LP Turbines can also be used to control the humidity of the indoor farm air without having to waste water by venting off damp air. Further water savings can be made by using rain water drained off the patios for irrigation.

Intensive vertical farming will free up agricultural land for growing trees. These could be planted in the same locality as the flats, creating community woodlands that mop up CO2 and create a space where kids can have adventures.

10 Cancel HS2 and use the money to double the capacity of our existing rail network instead

On this linked webpage we explain why high speed trains such as HS2 produce a far larger carbon footprint than trains travelling at a slower 125 miles/hour. We also explain how, by using eddy current braking, we can safely double the passenger and goods carrying capacity of our existing network.

11 Building a new chemicals industry based on CO2.

Switching from oil to CO2 as the basic feedstock for the chemicals industry is possible using existing technology but is commercially unattractive because of the high cost of the energy required. This disadvantage can be overcome in an LP Turbine era.

Perhaps the most attractive product from this new chemicals industry would be zero carbon aircraft fuel. The required CO2 could be obtained by incinerating waste in oxygen as explained in Section 4 above.

If additional CO2 is required this could be extracted from the atmosphere. The technology for capturing carbon from the atmosphere by chemical methods already exists. LP Turbines offer new methods based on air cooling. – Essentially, our method is the same as that proposed for separating CO2 out of flue gases. But instead, the CO2 would be extracted from the air.

12 Incinerating high level nuclear waste

Highly radioactive nuclear waste is particularly difficult to dispose of because it has to go through several stages of radioactive decay before it ends up as a safe, non-radioactive element. During the decay process, carcinogenic nuclear particles and radiation are emitted. The decay process also produces heat. Depending on the radioactive isotopes involved, this decay process will probably take many thousands of years.

The only way to speed up the decay process is by by bombarding the waste with nuclear particles inside a specially designed nuclear reactor. This acceleration process is often referred to as ‘incineration’ but is an entirely different process to burning rubbish in an incinerator.

Humanity has only got two choices for dealing with this waste:

(i) We build molten salt nuclear reactors that can incinerate the waste.

(ii) We hide it away somewhere as an embarrassing problem that we don’t want to face up to. But, by doing this, we are placing a curse on humanity for many, many generations into the future. Try to imagine how long ago it was since the Romans invaded Britain and multiply this time by a hundred. That gives you some idea of the amount of time our high level nuclear waste will remain dangerous.

Fortunately the type of nuclear reactor required for incineration is inherently fail-safe. It switches off automatically if it overheats and it can’t be switched on again by mad scientists. This makes the reactors far safer than the designs that were destroyed in the Chernobyl, Fukushima and Three Mile Island disasters. On this linked webpage we explain how Latent Power Turbines could further improve the safety of these incineration reactors.

If we have the aim of incinerating all of our UK nuclear waste in a reasonable time, say 100 years, we could end up generating far more electricity than we currently need. This will open up new wealth creating opportunities for the UK that are currently beyond our dreams.

Other measures that need swift implementation to fight climate change include:

- Reducing our consumption of meat and dairy products.

- Adding seaweed to cattle diets to reduce methane production.

- Increasing our rate of planting trees.

- Encourage agricultural techniques that promote carbon capture in the soil. For example minimal tillage, cover crops and crop rotation.

Conclusion

The proposals outlined above are likely to lead to a significant increase in material wealth for the whole of humanity in the years after 2025. Paradoxically, this should be good for the environment because the evidence from the developed world is that with increased wealth, people tend to have smaller families.

According to the latest United Nations report (17 June 2019), the world population is expected to grow from its current 7.7 billion and peak at almost 11 billion in 2100.

[https://www.un.org/development/desa/en/news/population/world-population-prospects-2019.html]

In a greener world where wealth also increases, this peak population may have to be drastically revised down.